Metrology – Organ bench

COMPETITION & COLLECTION

LORRTEC has all the equipment necessary for the metrology of the various mechanical components of an engine .

Several organ benches make it possible to test and control most of these components :

- Cylinder head blower

- Injector test bench

- Cam profile reading bench

- valve spring auger

- Mechanical injection pump bench type Lucas (Cosworth DFV/BDA…), Kugelfischer (BMW M12/7…) or even BOSCH (Porsche 911Gr4…)

Presentation of LORRTEC’s engine parts and metrology control activity

Engine metrology

Metrology is essential to guarantee the proper functioning of an engine. After dismantling it, each internal part is analysed, measured and if necessary tested on an organ bench and/or X-rayed (for example for titanium parts such as F1 engine connecting rods). The surface condition after reaming and/or honing is also measured (Ra, Rz, etc.) in order to guarantee the best possible contact with the pistons and rings.

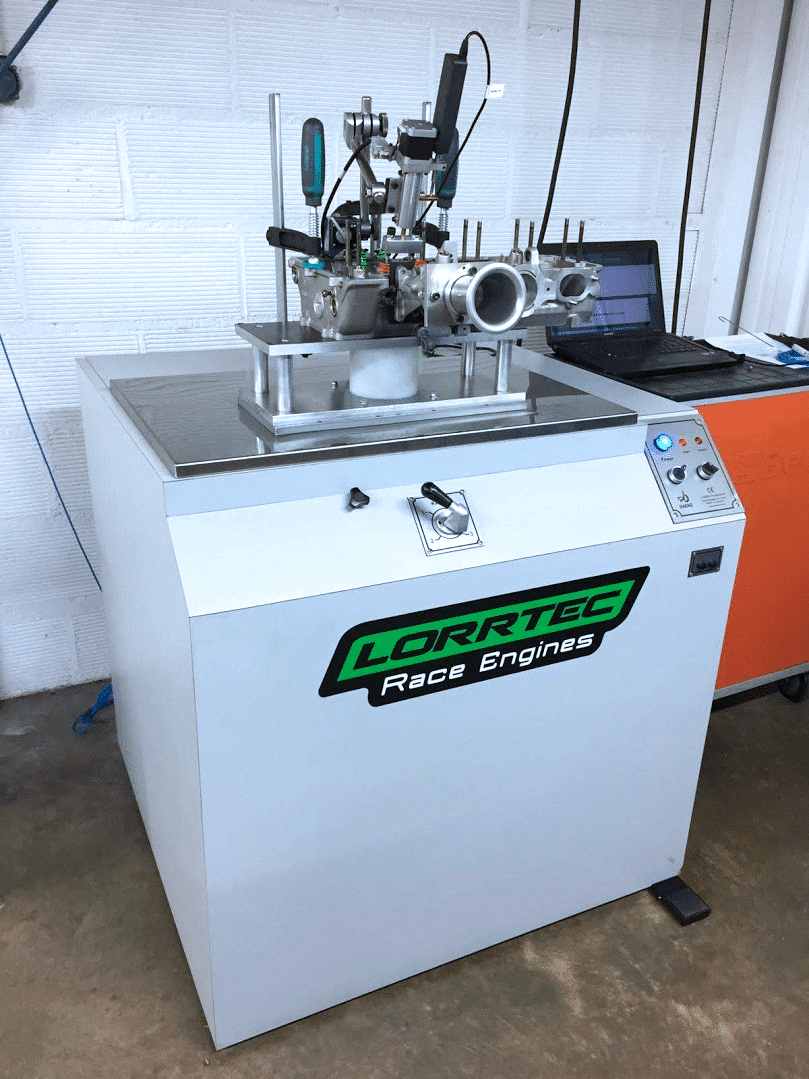

Cylinder head blower

The cylinder head blower determines the aerodynamic design of the cylinder head ports, as well as the shape of the valves and seats in a performance optimization framework.

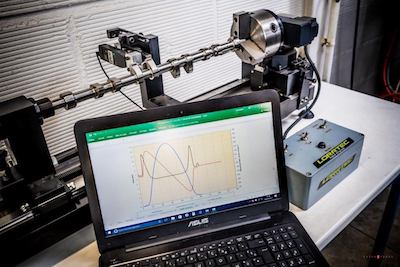

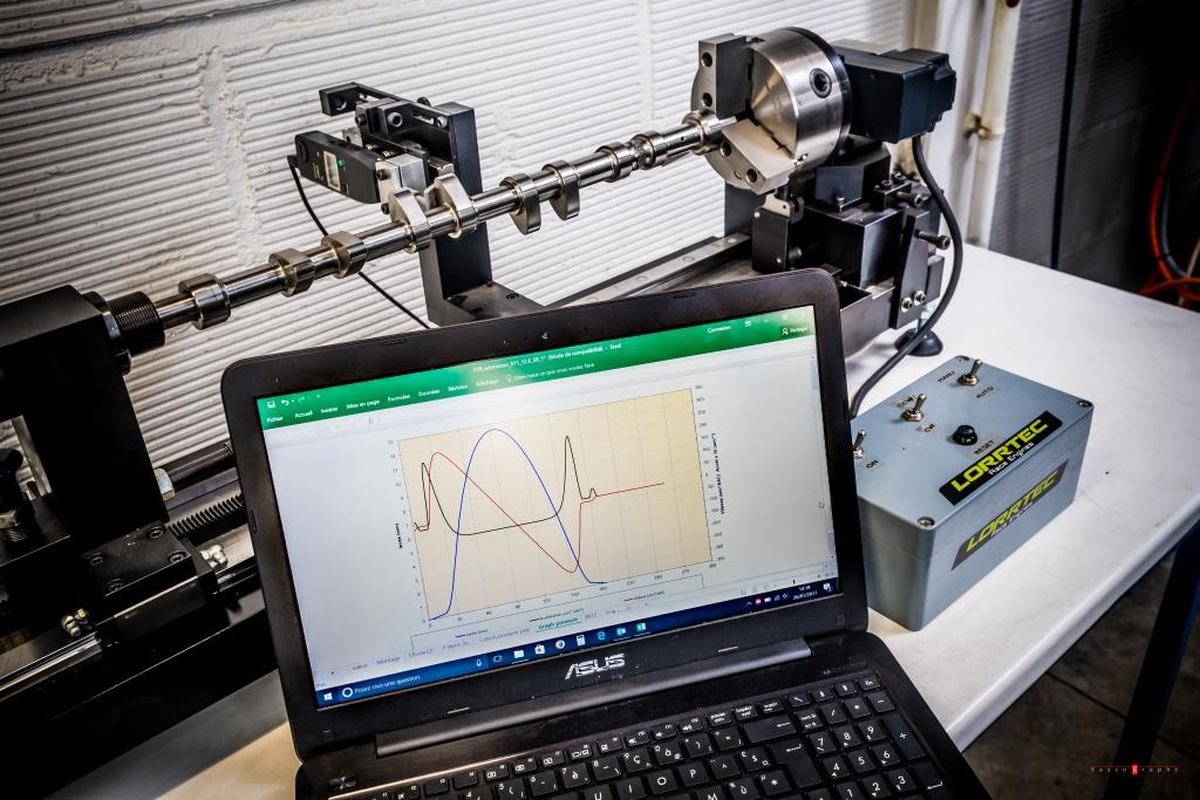

Camshaft bench

The cam reading bench (for camshaft or mechanical injection pump cam) makes it possible to work on the distribution laws, to check existing diagrams and to reproduce certain parts (reverse engineering).

Injector bench and injection pump

The injector bank guarantees the equivalence of flow rates between all the cylinders for better engine performance.

Our mechanical injection pump bench allows us to revise and optimize the pumps in correlation with the engine tests on the bench.

QUOTATION

All the activities of LORRTEC